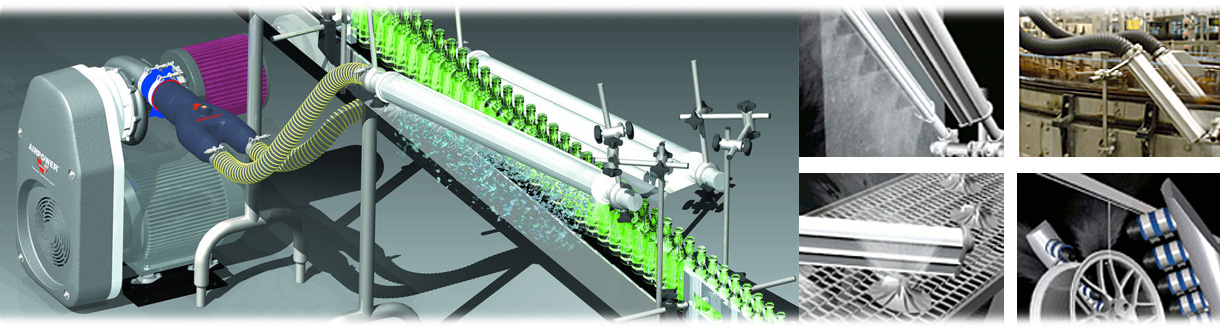

Air knife drying systems

AIRCOM air knife drying systems dry products prior to labeling, ink jet coding, packaging or other secondary operations. Other uses include anti-static, cooling and cleaning.

Our Air Knife Drying Systems, furnished with Vortron and Elmo Rietschle low-pressure blowers and teardrop air knives, are the most effective and efficient approach to dry or clean your products.

Our drying systems typically operate at pressures of 2 to 4 psig. The result is a steady stream of warm dry air exiting the air knives at velocities up to 45,000 fpm.

Features and benefits

- Low pressure air = low energy consumption vs compressed air

- Blower inlet filter = clean air discharge

- Dry, clean and oil free air = better looking product

- Low-pressure air = safety

- Effective drying at high conveyor speeds = increased production speeds

- Reduced sound levels when compared to a compressed air nozzle

The effectiveness of a drying system depends on the quantity, length, location and angle of air knives with an optimized balance of air velocity and mass flow.

Our technical sales people can assess your needs and offer a suitable system.

Typical Drying Applications

- Bottles & Cans

- PC boards and electrical components

- Coiled Steel – Wire & Cable

- Plastics & film extrusion

- Confectionery & food

- Toppings

- Machined parts

- Packaged meat, fish and poultry

- Produce, fruit & vegetables

- Conveyor belt cleaning / drying

- Static control

- Cooling